Reared in the northernmost tip of Japan, premium scallops with concentrated umami savoriness and sweetness

Japan-produced scallops featuring a strong sweetness, rich umami savoriness, and springy texture. A superbly delicious dish as sashimi, sauteed in butter or fried, in pasta or just added to mixed savory rice. This main producer of scallops in Japan is the village of Sarufutsu in Hokkaido, the “northernmost village in Japan”.

Sarufutsu is on a similar line of latitude to Montreal, Canada, with a low average temperature of 4.4 degrees Celsius throughout the year. It is a severe natural environment with a north wind and ice floes surging into the Sea of Okhotsk during the long winter. Scallops reared in this region have strong sweetness and umami savoriness, with a firm texture of the adductor muscles giving an excellent thick chewiness. As well as being highly rated in quality, Sarufutsu village has also achieved fame many times for the top catch in Japan. What is the nature of the “Rearing and catching fish industry” of Sarufutsu village that holds the key to its volume of catch?

Scallop hatchlings are reared for a year, and once they are spat of around 3-5cm, they are released into the sea.

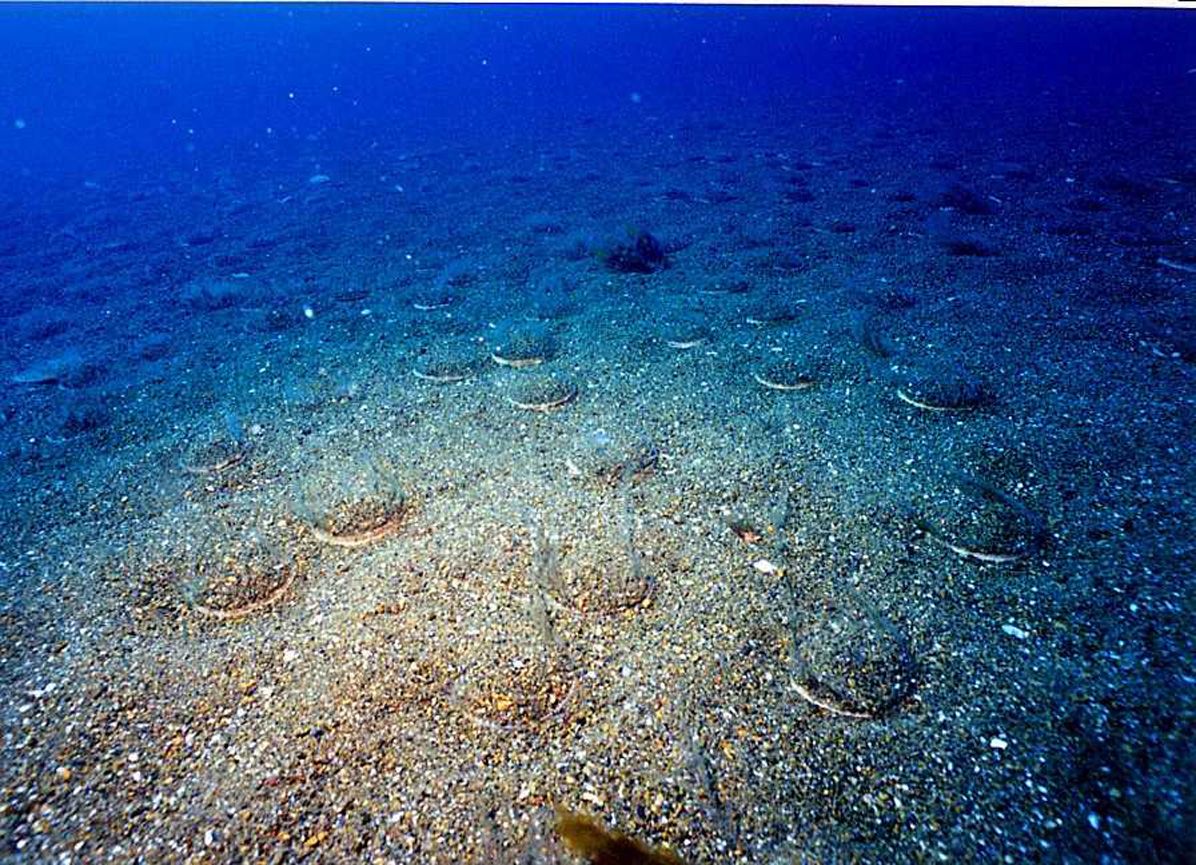

“The top feature of scallop fishing of Sarufutsu village is its ‘Rearing and catching’ industry. We buy scallop spat from spat production cooperatives of other service areas, release them into the sea, and with suitable management we rear them to a large size and then catch them. Since the seabed off the shore of Sarufutsu village has more fine gravel than sand, the spat won’t easily get covered in sand even in stormy seas, so it has advantages from an environmental aspect for the rearing of scallops. However, until now, we have not continued fishing just with the benefit of this environment.

This is explained by Mr. Masahiko Kimura from the Sarufutsu Fishing Industry Cooperative Association. Herring fishing and scallop fishing thrived in Sarufutsu village from olden times, but during the 1950s, the catches of both decreased dramatically, and many fishers had no choice but to quit their business.

After many attempts of trial and error, the Sarufutsu Fishing Industry Cooperative Association made the change from a straight fishing industry to a “Rearing and catching” fishing industry. From 1971, and over the next 10 years or so, they took the plunge and carried out the scallop spat release project. This decision reaped success, and Sarufutsu’s scallop catch increased greatly.

Scallops reared in the bitterly cold Sea of Okhotsk make a fine dish.

The “Rearing and catching” fishing industry involves dividing the fishing ground into four zones and releasing scallop spat into one zone every year. They are caught after being reared for four years in the sea, in the method known as “4-round system”. From April to around early May, approximately 250 million spat are released over the course of a month. With a view to guarantee volume and distribute risk, spat are bought in from fishing cooperatives in six areas of Hokkaido. Since it is necessary to release spat on the day they are acquired, they watch for a timing when the sea is not rough between the place where they are acquired and Sarufutsu where they will be released.

During the fishing season from mid March through the end of November, 11 ton of scallop are caught daily by each boat. At the height of the season, from around June through August, fishers leave port at 4:30 in the morning.

A large rake attached with a net bag called a “Hasshaku” is sunk into the sea and pulled along for around 15 minutes, scooping up the scallops from the seabed into the boat. The fishers carry out a selection process by hand for all the scallops, one by one. Apart from those which have died and are just shells, the scallops that are still small are released back into the sea. If star fish are pulled up, which are the natural enemy of scallops, they dry them in processing facilities in order for them to taken away by fertilizer producers. Sorting 11 tons of scallops every day is a hard task even for experienced fishers. Once returned to port, so as not to lose their freshness they are immediately transported. They are either loaded into trucks and dispatched to various destinations, or a portion is carried to the adjacent processing factory.

Catching scallop by pulling a Hasshaku around the seabed. In places where there are lots of scallop, sometimes there can be one catch of 3-4 tons.

In order to maintain a stable volume of catch, suitable management of the fishing ground throughout the year is important work. “Staff board the fishing ground management boat that belongs to the fishing cooperative, catch sample scallops, estimate the condition of each zone from the volume and state of growth, and report to the trustees. If they judge that they cannot forecast the catch volume from that, they consider other ways round such as catching scallops from other zones”, says Mr. Kimura. He also says that to check the steady growth of the scallops, samples are taken around 500 times every year.

The scallops of Sarufutsu village, reared carefully in this way by scallop industry professionals, are processed into frozen adductor muscles called “Tamarei (frozen scallop balls)” and dried adductor muscles, and transported to various places in Japan and abroad. The freezing factory located on the quay side has obtained the EU’s HACCP (Hazard Analysis and Critical Control Point) certification, and has also taken on transportation abroad, including to the EU.

The “Tamarei” made in Sarufutsu village are mainly transported to China, the U.S., Hong Kong and Taiwan. The freshly caught scallops are carefully shelled one by one and immediately frozen, they are used a lot as the ingredient of sashimi and sushi particularly in Hong Kong and Taiwan. “The way we have an organized system of stable catching and supply of products is acclaimed in Japan and abroad. Sarufutsu Village Fishing Cooperative is the pioneer of Tamarei manufacture. The Sarufutsu Village Fishing Cooperative brand was recognized around the world before any other, and is widespread”, says a spokesperson for the Hokkaido Federation of Fisheries Cooperative Associations.

The four buildings of the freezing factory process a total of around 70 tons of scallops per day. It only takes about 30 minutes from when the scallops mount the conveyor belt until they are frozen. This speediness is the secret to keeping their outstanding freshness.

The “mantle” attached to the adductor muscle (a part surrounding the adductor muscle), etc., is carefully removed by hand.

After washing the adductor muscles in sterilized seawater, they are rapidly frozen to minus 40 degrees Celsius.

Dried adductor muscles, matured slowly by drying them in the sun, are also a popular product abroad. The caught scallops are carried to the processing factory and immediately steamed in their shells in a steamer, have their mantles, etc. removed by hand, and then boiled in salt. Having removed the water content using a roasting and drying apparatus, they are dried by moving alternately between a warm-air drying machine at approximately 50-55 degrees Celsius and a dehumidifying drying machine at approximately 23 degrees Celsius. Then a good weather day is chosen to dry them outside. Next, they are packed in wooden boxes and left to mature well. Processing them over a total of 40 days finishes them off with a superb flavor of tightly concentrated umami savoriness.

By drying them in the sun, the umami savoriness becomes deep and profound.

Dried adductor muscles with their crispy texture soaked in water will create stock full of umami savoriness. You can use them in many different ways, including in soup and mixed savory rice.

Also, the end of 2022 saw the announcement of a helmet (HOTAMET) created from a new material that made effective use of the scallop (hotate) shells that had been discarded to date as marine product waste. It was developed by long-established plastic manufacturer of Osaka, Koushi Chemical Industry using discarded scallop shells from Sarufutsu village. Shells that have finished in their role of protecting the body from enemies now take on a new role of protecting people as helmets - as well as being an attempt to contribute to SDGs. “Initially we plan for them to be used by our fishers as protective equipment. At Sarufutsu village, our efforts are not limited to utilizing the Sarufutsu scallops loved by people all around the world; we will continue to look into projects for realizing a sustainable society”, comments Mr. Koichi Ito, Head of Sarufutsu village.

Using the new material “Shellstic (Karastic) ” developed from a base of scallop shells, with their main component of calcium carbonate, and recycled plastic, the “HOTAMET” is created incorporating a design that is the structure of a scallop shell.

Scallops are an ingredient that goes well in many different dishes, but here we will introduce the dish “Scallops boiled in milk” using specialty milk produced in Hokkaido, as are the scallops. Pour 2 cups of milk into a small saucepan, put on a low heat, dissolve in 3 tablespoons of miso, add and mix in half a teaspoon of sugar and 1 tablespoon of butter, and take off the heat. Place scallop adductor muscles - cut to half the thickness, carrot - finely sliced and parboiled, enoki mushroom, spinach - parboiled and cut into easy-to-eat lengths, leek - thinly cut on the slant, together with tofu in a pan. Pour in soup made from milk, boil for about 2-3 minutes on a low heat and serve.

The flavor of milk and miso match the deep and profound umami savoriness of the scallops.

Reared in a severe natural environment, and with a concentrated deliciousness as you pop them in your mouth, these scallops will enchant anyone with their rich taste. With frozen adductor muscles and dried adductor muscles at hand for everyday use, your cooking repertory will grow in leaps and bounds.

Related articles:

“Baked scallops with garlic and parsley” recipe

“Salad with baked scallops” recipe

“Herb-Roasted Scallops” recipe

Extracted and recomposed from the Ministry of Agriculture, Forestry and Fisheries PR magazine “aff”, February 2022 issue.

Sarufutsu village, Hokkaido

Sarufutsu Fishing Industry Cooperative Association

Established in 1949. Main fishing industries are scallop dredge-net fishing, as well as hair crab basket fishing, salmon and trout fixed-net fishing, hen clam dredge-net fishing, octopus box-trap fishing, basket clam fishing, etc. In 1971, was the first to carry out large-scale release of scallop spat in Japan. Provides various processed items, from fresh scallops in their shells, to frozen adductor muscles, dried adductor muscles, soft adductor muscles, etc.

https://www.hotatebin.net/